About

HERMANNS Silo GMBH

HERMANNS Silo GMBH is more than a 100-year-old company that designs and constructs Dry Bulk Handling Solutions for their global Clients and Partners in accordance to the Market needs. Depending on the material to be transported (powdered or granulated products), different requirements regarding load, volume, type of tank and chassis must be met.

The Products produced in the partner countries are in accordance to these plans, specific country regulations accompanied by supply of important parts from HERMANNS Silo GMBH. The heart of all “V” type tank and hopper type tank semi-trailers is the Aeration, Discharge and Closure device “System HERMANNS” which makes it possible that the Tank semi-trailers can be completely discharged, fast and without any problems.

HERMANNS also supplies complete Tank semi-trailers in unrepresented Markets.

History

From the beggining till this time

We will take you to a little jouney througt time from HERMANNS-Silo GmbH.

1901 - 1954 Von Stromaggregaten bis Zementransporter

1955 - 1970 Zementauflieger für China und Frankreich

1971 - 1999 "V" - "Euter" - Auflieger, Fertigbetonmischer, Muldenkippen ...

2000 - 2003 "Think global, act localy..."

2004 - 2018 "New Applications....New Markets!"

Products

Bulkers

Dry Powders & Granulates are usually transported in Bags, Drums and even in loose condition. It is observed that for big consumers, it is not interesting to, “Bag it”,“Move it” and “Debag it”; as it involves a lot of Costs, Wastages and Multiple Handling. Some products are not Environment–friendly and cause pollution. Transit losses & Moisture damage are other extraneous factors adversely affecting the products during its movement to the Destination.

Dry Bulk Mobile Tankers (Bulkers)are a great way to transport dry materials without any of the above problems. The product Quality is intact, and the material reaches its destination, in the same way it was dispatched from the Suppliers.

The bulkers are fitted with a Pneumatic Conveying System and Safety Devices, which can discharge the product into the final destination Storage Silo/Yard safely. The very efficient HERMANNS CONVEYANCE DEVICE & OTHER DISCHARGE SYSTEMS results in high evacuation efficiency, making the discharge virtually complete and close to 100% empty. Now you can carry back another product if you wish to.

You can carry in bulk all materials such as: Cement, Fly Ash, Alumina, Soda Ash, English Clay, TiO2, Salt Chemicals,etc…..

Anything dry and powdered, which needs to be transported in bulk.

Containers

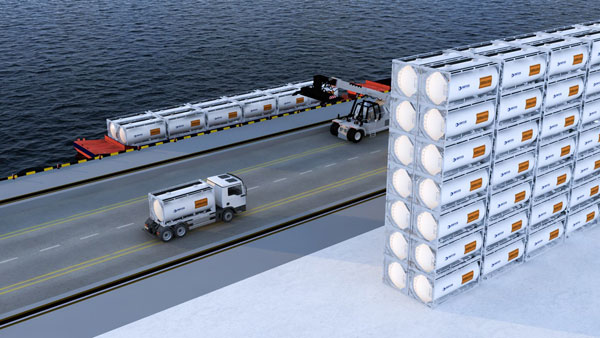

Combi-lifts

In collaboration with Velsycon (Germany) we now offer “Interchangeable Mini Silo with Combilifts”. It's an Innovative delivery concept where the product is delivered in Small Silos to The Client Locations. A New-age solution that saves cost of of Bags, Bagging, Labour, Godowns, etc., also improves efficiency and eliminates air pollution.

The COMBILIFT system can Pick up, Set down, Put down and Tilt swap bodies and exchangeable silos of different standards. Thus, we offer transport solutions for applications such as disposal, construction, plastics, flours/powders, food chemistry, etc.

Based on our market experience we can offer our clients versatile task solutions and a thoughtful all-round service. You will receive a vehicle, charging system and container from one source as well as guaranteed functionality right up to intersection compatibility. We assist you with the task analysis, provide detailed information on the systems and can be reached around the clock if required.

Built to German Quality & meeting nearly all International Standards, we can mount the Combilift Systems to virtually any Truck Model. Semi-trailer Versions are available, ready to be coupled to any Prime Mover.

Please send us the Truck Information and we would carry out a feasibility study for you.

Accessories

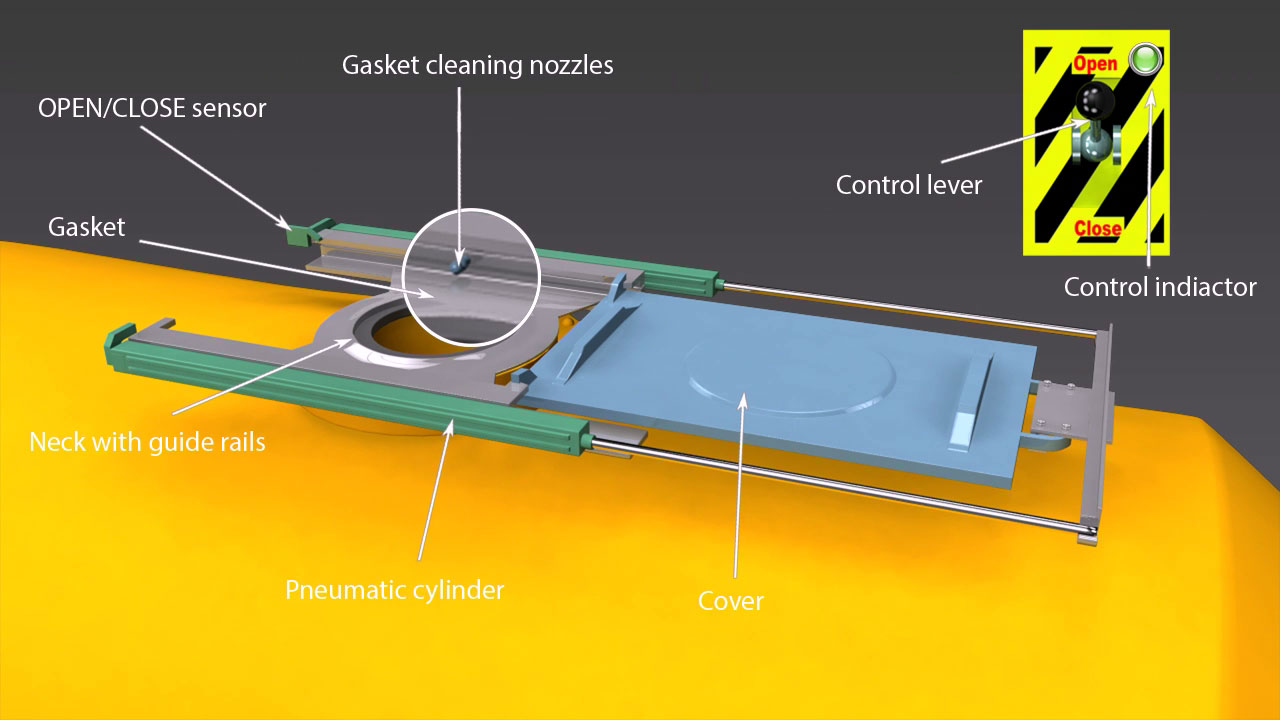

Sliding Covers

Safe and Efficient Loading by Pneumatic Hatch Covers. All Bulk Tankers are generally Equipped with Manholes or Hatch Covers on the top side of the Tank, for Loading. These Manually Operated Covers require a person to Climb on top of the tanker, each time when loading is to be done. Various Safety systems are adopted by Companies to ensure safety in Loading Operation. This process is costive and involves manual labor. Also slows down the loading thereby bringing inefficiency.

Safe and Efficient Loading by Pneumatic Hatch Covers. All Bulk Tankers are generally Equipped with Manholes or Hatch Covers on the top side of the Tank, for Loading. These Manually Operated Covers require a person to Climb on top of the tanker, each time when loading is to be done. Various Safety systems are adopted by Companies to ensure safety in Loading Operation. This process is costive and involves manual labor. Also slows down the loading thereby bringing inefficiency.

HERMANNS has developed a perfect solution to end these problems.

Pneumatic Operated Sliding Covers can be installed on New Dry Bulk Tankers and can also be retro-fitted on the existing bulkers. These covers are designed to operate up to 2 bar pressure and are built in accordance to the PED.

Operation box on the ground level, opens & closes the Cover whenever needed. No one has to climb on top of the tanker anymore. Brings Safety and increases Efficiency at loading locations.

Accidents can be avoided and precious Human life can be saved.

Self-sealing, pressure-tight without external control air, compressed air is only required for opening and closing. Easy and low cost maintenance, long life of the seals.

Elements for aeration and conveyance devices

- aeration hoses for silo semi-trailers and stationary silos for powdered products

- aeration cloths for silo semi-trailers and stationary silos for powdered products

- flow pipes for internal conveyance of powdered products

- aeration funnels for silo semi-trailers and stationary silos for powdered products

Discharge device System Hermanns

Application

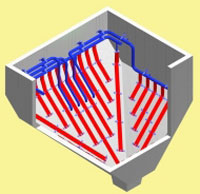

A hose system of special textile, which is permeable to air on one side, is applied in silos or tanks so that stored powdered bulk goods can be aerated for transport. Fluidization air, which is fed evenly over the total cross section guarantees a continuous discharge and avoids any funnel flow inside the silo.

The need for air and energy is remarkably low. Each silo can easily be refitted with this system according to the local circumstances. The aeration hoses with a width of about 110 mm can also be refitted in all silo geometries. Fixing devices are available for every silo material.

Pneumatic conveyor system

Application

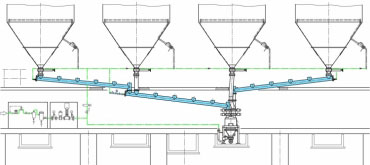

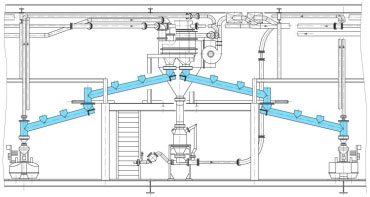

The specially developed pneumatic conveyor pipes prove themselves as simple conveyor devices for powdered products. They create a fluidized bed which guarantees a low-wear, dust-free and maintenance-free transport. Rotary parts (e.g. screws) are not necessary. The hand holes permit an easy control of the conveyance respectively cleaning without dismounting the pipes. This component is also flexibly usable and keeps energy requirement low.

Mounting options

The distances are almost unlimited provided that there is sufficient height for mounting the pipes.

Construction

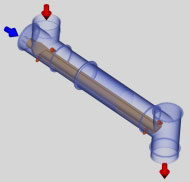

They are two different types of pneumatic conveyor pipes:

DIN pipes

Flanged pipes

With the use of pipes there is an easy connection to the components which lie in front of and behind them. Connection pieces are not necessary. Fluidized air enters via one or two aeration hoses System Hermanns. For this purpose compressed air with an operating pressure of 0.5 to 0.7 bar must be available. Air volume depends on the flow rate and the product type.

3D photo - pneumatic conveyor pipes.

Pneumatic conveyor pipes in the BMW core moulding.

Two aeration hoses in one pneumatic conveyor pipe.

Pneumatic conveyor pipe filled with quartz sand.

Example of installation of pneumatic conveyor pipes to convey quartz sand and feldspar in pneumatic conveyor systems. D - Haldensleben

Example of installation of pneumatic conveyor pipes in BMW core moulding. D - Landshut

Rail & Marine Projects

Partners

Bahrain, Oman, Qatar, United Arab Emirates

Al Shirawi Equipment Company L.L.C.

India

Meher Trailers Private Limited

Kuwait

Al Mulla Industries Co. W.L.L.

Ecuador

Aceros Inoxidables Peralta Ca. Ltda.

Jordan

Kawasmi Trading and Land Transportation Co.

Europe

Danteco Industries BV

Europe

Velsycon GmbH

Contact

Privacy Policy

1. Data collection and processing of http-data

Our webserver collects information (browser, date and time) as soon as you visit our website and make a file inquiry. These are no personal information. It is not possible for us to identify you from this data. They are only used for statistical purposes. They will not be given to third parties. We do not combine these data with other data. After the statistical analyis they will regularly be deleted within one week.

2. Use of personal data

Personal data will only be used from us in the way given to us. We use personal data for advertising purposes / market research as well as description of our services with your express consent. You always have the right to revoke your consent. Information on processing purposes will be given at the appropiate places of our website and is not subject to later change. They will only be given to third parties without your consent in case we are legally obliged to do so.

3. Use of cookies

Cookies are data which will be sent from the webserver to the browser of the user and stored for a later inquiry. You will decide whether cookies can be collected by configurating your browser in such a way that you will be informed before the storage of a cookie. A cookie will only be saved with your express acceptance. We only use cookies to get information about the use of our web offers as well as for statistical purposes. Our cookies contain the following data: The data do not contain any personal information. They will not be combined with personal data given by you.

4. Right to demand information

Our webserver collects information (browser, date and time) as soon as you visit our website and make a file inquiry. These are no personal information. It is not possible for us to identify you from this data. They are only used for statistical purposes. They will not be given to third parties. We do not combine these data with other data. After the statistical analyis they will regularly be deleted within one week.

5. About us

This is the privacy policy of HERMANNS Silo GMBH, Konstantinstr. 64 , 53179 Bonn Germany, homepage: www.hermanns-silo.com. If you have any questions regarding this privacy policy, please contact us by post or e-mail.

HERMANNS Silo All Rights Reserved © 2018